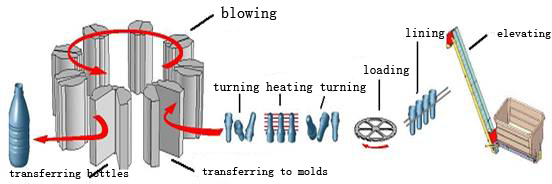

Adopts latest blowing idea and world leading technology to our revolutionary high speed blowing technology. Equipped with world renowned components such as German R+W clutch, TOSHIBA infrared lamps, BOSCH REXROTH linear guide, Swiss SEITZ high pressure air valve, AIRTEC stretching cylinder, SIEMENS control system, OPTEX temperature controller, PARKER/BOSCH REXROTH brake cylinder, SEW/NORD motor, SKF/NSK bearings, etc.

Key Features

Stretching Guide

- Mechanically control speed of stretching

- Prevents uneven stretching caused by turbulence of blowing air

- Ensures shape and quality of the bottle are consistent

Preform Rotating Structure

- Ensures the preform is kept at upside down orientation in the oven

- Prevents the bottle neck from overheating and deformation

Adequate Spindle’s Distance

- Accommodates various bottle neck size (0 – 38mm pitch circle diameter)

- Optimised for infrared heating and energy saving

Well Designed Mould Clamping Cam and Robotic Arm Cam

- Smooth operation with reduced vibration and noise

- Synchronization of preform loading and mould clamping

Straightforward and Easy

- Mould switching without special tools

- Synchronization of preform loading and mould clamping

- User friendly operating system with alarm

Linear Type

Linear Type